Viticulture in Harxheim – The company history of Pflugbau Bücking

At the eastern end of Harxheim lies the site of the Buchert locksmith’s shop. Until 1970, vineyard plows were produced here, which were known far beyond our region. Jakob Bücking, the grandfather of the current owner, founded the company in 1924.

The Bücking family originally came from Alsfeld in Upper Hesse. In the town there is a burgher house (Bücking House), from which probably Jakob Bücking or his ancestors came. The family came to Gau-Odernheim, where Jakob Bücking (1885 – 1957) grew up. In his childhood the railroad lines were built in Rheinhessen, this interested him very much. Jakob Bücking was a locksmith by trade. Initially, he worked in Gau-Odernheim at the agricultural machinery company Acker. Through the company, he also came to Harxheim, among other places, to repair machines on site. Opposite the present premises of the locksmith’s shop – at that time undeveloped wetlands – used to stand the inn of Jakob and Kathrin Mann. Jakob Bücking went there to have an after-work drink. At that time, he had seen vineyard plows at the Böhmer agricultural machinery company in Alzey, and he had the idea of improving them technically.

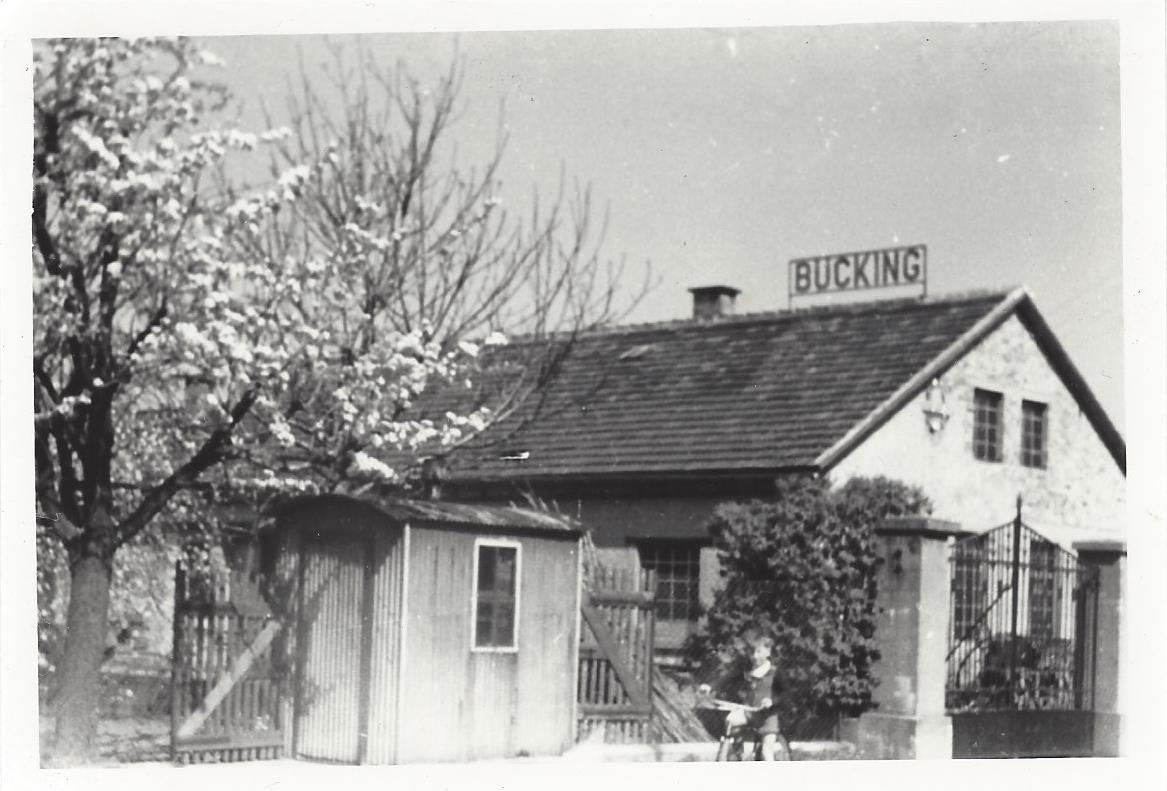

Bücking workshop building probably 1950s, in front left a second Harxheim weigh house (there was also a weigh house at the place at the scale in the center of the village)

Image source: Gerhard Buchert

Jakob Bücking entertained the idea of going into business for himself and putting his ideas into practice. As a future business location, his choice fell on the aforementioned wetland area, which was uninteresting from an agricultural point of view. He managed to acquire it at a very reasonable price. The nearby railroad station – the Amiche line, opened in 1896, passed by here – also made the property interesting for the procurement of materials and the expedition of its products. He had the site filled in and built his workshop here in 1924. Because of the constant wetness, no basement rooms were created.

By the way, there was a second Harxheim weigh house on the left in front of the company premises at that time, which was needed due to the freight traffic at the station. Jakob Bücking himself forged the gate to the company premises that still exists today, and the gate in front of the former Böhm bakery at Gaustraße 11 was also made by him.

After the start of the plow production, a considerable sales success was achieved quickly and the vineyard equipment gained a very good reputation among the winegrowers far beyond the Harxheim borders. From 1924 – 1970, a total of more than 10,000 vineyard plows were produced. The company developed accordingly well, had incl. apprentices, the company employed around 20 people and was an important employer for Harxheim at the time.

The plows were mainly sold in Rheinhessen and in the Rheingau region as well as on the Mosel, but there were also buyers in other German growing areas. The transport took place from the train station in Harxheim. As far as is known, no exports were made. Distribution was mainly through agricultural machinery dealers and farmers’ main cooperatives. Large customers, such as the Guntrum winery in Oppenheim, which ordered several plows in one order, were also supplied directly. Good customers were given a miniature plow – usually a journeyman’s piece – to display in their showrooms, a vivid and fully functional advertising medium. Before the outbreak of the 2nd World War, a plow cost approx.120 Reichsmark.

Jakob Bücking – known for his clear language and sometimes very robust treatment of fellow human beings – was no friend of the Nazi regime and an avowed opponent of Hitler. He expressed this openly. A line-loyal tax collector who came to the company in the mid-1930s was once dissuaded from his planned collection with rude words and the ever-ready sledgehammer, and was never seen again in the locksmith’s store after this memorable encounter with Jakob Bücking.

At the beginning of the war in 1939, the company had a large stock of individual parts for plow production, which was sufficient for the assembly of 500 devices. Since metal was subject to compulsory management as a raw material vital to the war effort, there was always the danger of having to hand over the material in the event of unannounced inspections. Well hidden on the company grounds, a plow was always assembled when needed and used as a coveted barter item during wartime. The winter months were usually used for the production of the individual parts for the plows. From spring into the fall, customer demand began, and assembly usually took place after orders were received.

Most of the parts for the plow were made by the company itself. This also applies to the steel springs formed from continuous spring wire in a complicated process, which were required for the movable outer shares.

The shares of the plow – usually there were five – were called goosefoot shares after their V-shape. These were held in place by molded coulter clamps. These clamps were not manufactured in-house, but were purchased from foundries in Kaiserslautern and Gevelsberg in Westphalia.

The guide carriage in the middle of the frame, which served to adjust the width of the plow, bore the inscription Jak. Bücking Harxheim and D.R.G.M (Deutsches Reichsgebrauchsmuster).

The plow remained technically largely unchanged during the decades in which it was produced. However, the production process has been partially simplified. At least parts of the plow were patented.

Initially, the plows had wooden handles. The installation of the handles was complicated and individual to the individual plug. First, the handle was briefly placed on the end piece, which was made red-hot, so that the wooden part fitted exactly to this, and immediately pulled off again. Then the iron end piece was heated again, the wooden handle was put on, a washer was put on and riveted. In later models, the wooden handles were replaced with metal versions.

The company livery of Bücking plows was generally silver. There were also plows as attachments bspw. for single-axle tractors of the company Holder and many others individually manufactured. In such cases, the equipment to be delivered was painted according to the color of these companies.

The track width of the plow could be variably adjusted to a vineyard row. As a significant feature of the Bücking plow, an additional movable share could be attached to the sides of each of the rear shares. These were used to remove weeds from under the vines. The movable knife-shaped share retracted by means of a spring pull when it met resistance such as a vine, so that the vine was not injured. The great advantage was that this allowed to remove weeds not only in the rows, but also between the vines.

The plow was not a plow (deep plow) in the true sense. The coulters did not go more than about 4 cm below the ground. You should get the weeds from the root, that is, keep the soil in the vineyards free of weeds.

The vineyards were not greened at that time. The negative effect was, among other things, that the soil was washed away when it rained and had to be brought back to the vineyards. It required a lot of experience from the winemaker, who led the plow behind the horse or a winch, to guide the team – without causing damage to vines and material – through the vineyards.

The operation was, of course, simply set up by today’s standards. For example, there were no showers for employees to clean up after their work was done. More than a wash bowl or a bucket and washing sand were not available. For basic cleaning in winter, the ice-cold wash water was then brought to a comfortable temperature with the help of a red-hot piece of iron thrown into the tub filled with water.

In 1970, Jakob Bücking’s grandson Gerhard Buchert took over the workshop from his mother Irmgard. The production of vineyard plows was discontinued from that time due to lack of demand. Since then, the company has focused on metalworking and building locksmithery.

References:

Conversations with Gerhard and Rosemarie Buchert